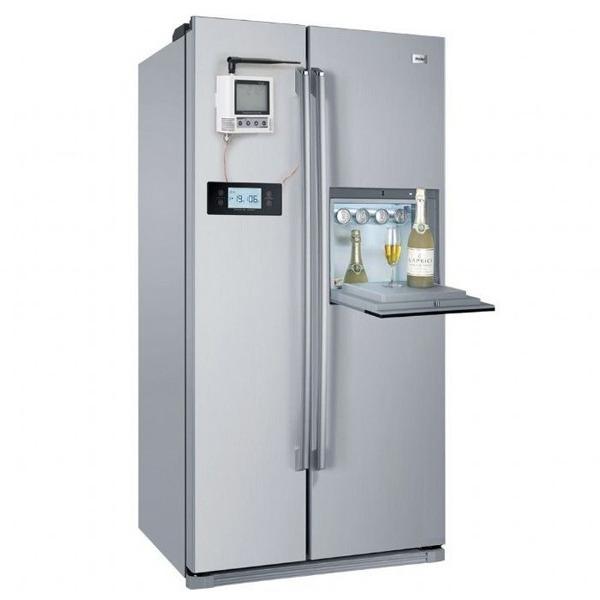

High-Quality Refrigerator Coating Solution for Durability,

Protection, and Aesthetic Appeal

Product Description

The Refrigerator Coating Solution is designed to provide superior

protection and enhanced aesthetics for refrigerators. This solution

is widely used on the metal surfaces of both the inner and outer

cavities of refrigerators, as well as other household appliances

such as radiators, oil tins, lamps, air conditioners, and range

hoods. Our coating solution offers excellent corrosion resistance,

durability, and a high-quality finish that ensures the appliance

maintains its performance and appearance over time.

Key Features of Refrigerator Coating Solution

1. Electrophoretic Paint Primer:

The foundation of our coating solution is an electrophoretic paint

primer, a water-based, environmentally-friendly product that

provides excellent adhesion to metal surfaces. This primer is

highly effective in protecting refrigerator components from

corrosion and ensures a smooth and even coating application. It is

free from heavy metals such as lead, cadmium, and mercury, making

it a safer option for both manufacturers and end-users.

2. Powder or Spray Finish Coating:

After applying the electrophoretic primer, we use powder or spray

paint for the final finish. The powder coating provides a smooth,

durable surface, while the spray paint offers a more flexible

option for intricate designs and colors. Both types of finish

coatings are available in a wide range of colors, including white,

gray, black, and custom hues to match specific design preferences.

3. Durable and Resistant:

The coating solution offers excellent resistance to various

environmental factors such as moisture, heat, and UV radiation.

This ensures the refrigerator’s exterior remains visually appealing

and functional even in humid environments or areas with fluctuating

temperatures.

4. Corrosion Resistance:

The electrophoretic primer provides outstanding corrosion

resistance, especially in areas prone to moisture exposure. This

ensures that the metal parts of the refrigerator are well-protected

against rust, which can degrade the appliance over time.

Applications of Refrigerator Coating Solution

1. Outer Cavity of Refrigerators:

The outer body of refrigerators is exposed to a range of

environmental factors such as dust, humidity, and temperature

changes. Our coating solution offers excellent protection from

scratches, fading, and corrosion, keeping the refrigerator looking

fresh and functioning properly.

2. Inner Cavity of Refrigerators:

The inner metal surfaces of refrigerators, including shelves,

trays, and compartments, are also coated to prevent rust and

degradation. The coating provides additional protection against

moisture build-up, ensuring that the interior components stay

durable and clean.

3. Additional Appliances:

Besides refrigerators, this coating solution is also ideal for use

on other metal surfaces in household appliances such as radiators,

oil tins, lamps, air conditioners, and range hoods. It provides

consistent protection and aesthetic appeal for a wide range of

products.

Benefits of Refrigerator Coating Solution

- Enhanced Aesthetic Appeal:

The coating solution is available in a wide variety of colors,

giving refrigerator manufacturers and users the ability to choose a

finish that matches their design preferences. The high-gloss finish

enhances the overall look of the appliance, making it a stylish

addition to any kitchen or home.

Our coating provides a strong, durable layer of protection that

extends the lifespan of the refrigerator by preventing rust,

corrosion, and physical damage. The powder or spray finish also

resists fading over time, ensuring the appliance maintains its

visual appeal.

- Environmental Protection:

The use of water-based electrophoretic primer ensures that the

coating solution is eco-friendly and low in volatile organic

compounds (VOCs), making it safe for both the environment and the

end-users.

- Excellent Corrosion and Scratch Resistance:

The combination of electrophoretic primer and high-quality finish

coatings creates a resilient layer that resists damage from

everyday use, including scratching and scuffing. This ensures that

refrigerators remain in top condition throughout their service

life.

The smooth, easy-to-clean surface provided by the coating helps

maintain the cleanliness and hygiene of the refrigerator. Dirt,

grease, and fingerprints can be wiped off effortlessly, making it

easier to keep the appliance looking fresh.

Application Process

1. Surface Preparation:

Before applying the coating, the metal surfaces must be thoroughly

cleaned to remove any dirt, oil, or rust. This ensures good

adhesion of the primer and paint to the metal surface.

2. Priming:

The electrophoretic primer is applied through the electrophoresis

process, which ensures an even and consistent layer of primer on

the metal surface. This step is crucial for corrosion protection

and smooth coating application.

3. Finishing Coat:

After the primer has cured, a powder or spray finish coat is

applied. The powder coating is baked in an oven to form a smooth,

durable finish, while spray paint is allowed to dry at room

temperature or baked for a stronger finish.

4. Curing:

The final coatings are cured at high temperatures to ensure that

they fully bond with the metal surface. This process also improves

the durability and scratch resistance of the coating.

Key Considerations and Tips for Refrigerator Coating

1. Proper Ventilation:

Ensure that the area where the coating is applied is

well-ventilated to prevent the accumulation of fumes from the

primer and finish coatings.

2. Curing Temperature:

Follow the recommended curing temperatures to achieve the best

results. Insufficient curing can lead to a weaker bond between the

coating and the substrate, reducing the durability of the finish.

3. Avoid Overexposure to Humidity:

While the coating is designed to withstand moisture, it’s essential

to avoid overexposure during the application process. Excess

humidity can affect the adhesion of the paint and the final

appearance.

4. Regular Maintenance:

Regularly inspect the refrigerator’s surface for any signs of

damage or wear. Cleaning the surface with mild detergent and

avoiding abrasive materials will help maintain the coating’s

appearance.

The Refrigerator Coating Solution provides an efficient and eco-friendly way to enhance the

durability, performance, and aesthetic appeal of refrigerators and

other household appliances. With superior corrosion resistance,

scratch protection, and an attractive finish, this coating solution

is ideal for manufacturers and consumers looking for a long-lasting

and attractive finish for their appliances. Whether you are looking

to protect the outer body, interior components, or both, our

coating solution offers reliable protection and visual enhancement

for refrigerators in any home.

Support and Services

We will provide the following technical support and services for

all products under the Jingtu Paint brand.

- Assistance with product installation and setup

- Troubleshooting and problem solving

- Guidance on proper use and maintenance

- Training and education on product features and functionality

- Regular software updates and patches

- Integration support with other systems or software

QA

1. What is the primary function of electrophoretic paint in

refrigerator coating?

Electrophoretic paint serves as a high-performance primer for

refrigerator coatings. It provides excellent adhesion, corrosion

resistance, and durability. The electrophoretic process ensures a

uniform coat that protects the underlying metal surface from

environmental factors like moisture and oxidation, extending the

refrigerator's lifespan.

2. Can the refrigerator coating system be used on both the interior

and exterior surfaces?

Yes, the refrigerator coating system is suitable for both the inner

and outer metal surfaces of refrigerators. It ensures comprehensive

protection, improving both the appearance and performance of the

refrigerator. The electrophoretic primer offers strong adhesion,

while the powder or spray finish enhances durability and

aesthetics.

3. How does the coating system improve the aesthetic appearance of

refrigerators?

The coating system, which includes powder or spray paint as the

finish, provides a smooth, uniform, and high-gloss surface. It is

available in various colors such as white, gray, black, and other

custom hues, allowing for better aesthetic appeal and

customization. The finish enhances the visual quality of the

refrigerator, making it look sleek and modern.

4. What are the key benefits of using electrophoretic paint as a

primer for refrigerator coating?

Electrophoretic paint offers several advantages for refrigerator

coatings:

- Superior Corrosion Resistance: Protects against rust and degradation from moisture.

- Uniform Coverage: Ensures an even and smooth application, which is essential for

both functional and aesthetic purposes.

- Durability: Provides a strong foundation for the topcoat, making it resistant

to wear, scratches, and environmental damage.

- Environmentally Safe: Free from heavy metals and other harmful chemicals.

5. Can custom colors be requested for the refrigerator coating?

Yes, the refrigerator coating solution is available in a range of

colors, including white, gray, black, and others. Custom colors can

be requested, ensuring that the refrigerator’s appearance meets

specific design requirements or customer preferences.